Introduction of New Generation of Gas-fired boiler Equipment

★TGR Series ultra-low nitrogen burners:

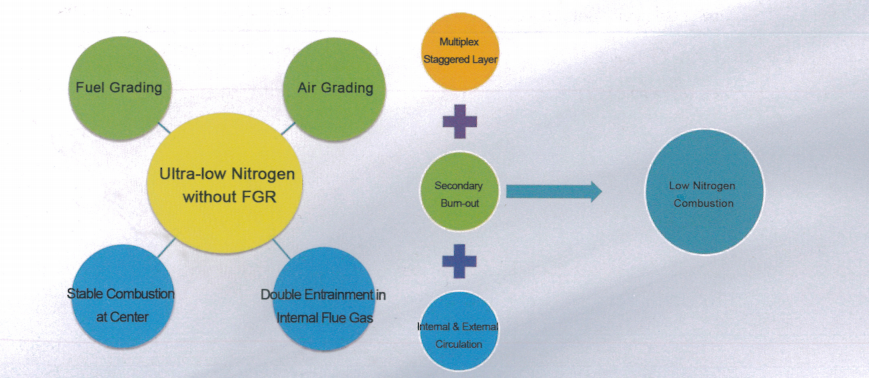

TGR series ultra-low nitrogen burners are developed and designed by Tsinghua University based on the latest environmental protection standards in China.It canoperate stably at a widely load range and ensure the NOx emission to be lower than30mg/Nm³emission standard

★System Solution:

According to the gas-fred characteristics of low calorfic value,high humiclity,highsulur and high NOx, it provides the users with the integrated and low-cost solution forlow nitrogen combustion+SCR denitrification +semi-dry desulfurization &dust removal,which completely solves the problems of tail heating surface blockage,corrosion andshort operation time of exhaust power generation boiler in the production industry.

★SystemApplication Scope of Product:

Carbon black exhaust gas,coke oven gas,blast furnace gas,Blue carbon gas,exhaust gas of mineral thermal furnace , multi-fuel mixture gas

★Features of Product:

①Non-standard customization,widely working conditionadaptability

②High regulation ratio design,flexible load adjustment

③Full combustion,ultra-low emission,energy saving andefficiency increasing

★Perfomance of Product:

Stable combustion ,emissions to be the lowest level at the same domesticproduct,Strong combination technical team by Taiyuan Boiler-Tsinghua University,Gas-fired ultra-low nitrogen combustion system has been formed with integratedof design,manufacturing,commissioning and testing,providing the User with thebest "boiler+furnace"solution.

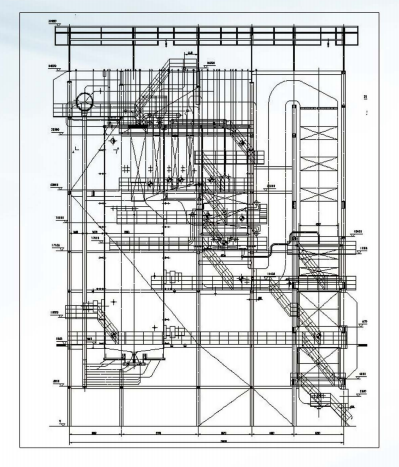

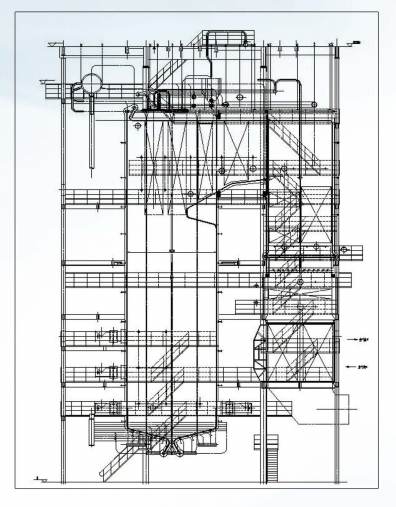

Carbon Black Exhaust Gas Boiler

Matched Power Generalor Set:20-40MW

Boiler Capacity:75-150t/h

Steam Pressure:3.82-13.7MPa

Steam Temperature:450-540℃

Boller Eficiency:85-90%

NOx Original Emission:≤150mg/Nm³

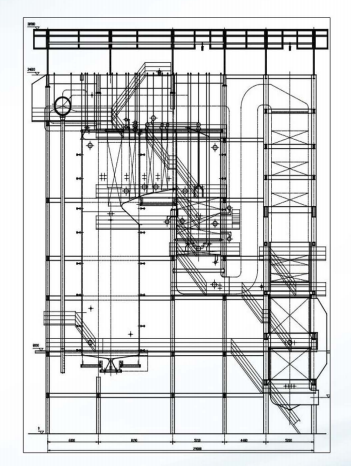

Coke Oven Gas Boiler

Matched Power Generator Set:20-100MW

Boller Capacity:75-330Vh

Steam Pressure:3.82-17.6MPa

Steam Temperature:450-571℃

Boller Eficiency:90-92%

NOx Original Emission:≤100mg/Nm³(Coke oven gas)

NOx Original Emission:≤300mg/Nm³(Semi-coke gas)

Blast Furnace Gas Boiler

Matched Power Generator Set:20-135MW

Boiler Capacity:75-450t/h

Steam Pressure:3.82-17.6MPa

Steam Temperature:450-571℃

Boiier Eficiency:89-91%

NOx Original Emission:≤50mg/Nm³

Natural Gas Boiler

Boiler Capacity:75-400t/h、58-116MW

Steam Pressure:3.82-17.6MPa

Steam Temperature:450-571℃

Boller Eficiency:96-108%

NOx Original Emission:≤30mg/Nm³(without FGR)

NOx Original Emission:≤20mg/Nm³(micro -FGR)